So it’s been nearly a Month since our shop flooded. Tons and tons of support poured into the shop via funds, positive thoughts, phone calls, etc… I can’t thank Lisa Ballard enough for setting up a “Gofundme” account to which many folks made donations to help us get back on our feet. Lowbrow Customs, ChopCult, Biltwell, Monstercraftsman and many many others all jumped in to help out. And we can’t be thankful enough for that…

I was even all packed up and ready to leave for the Ramble Tamble the morning of the flood. You can see all my gear on Slight Hell’s trailer…

I was supposed to be in Kentucky for the Ramble Tamble while our shop was flooding. While I missed that trip, it seems all my friends and folks I knew going had a blast.

Now I’m cleaning up my shop, dealing with all the flood mess, rebuild, etc.. And I get a text message from a customer. He says “Man, I totalled my bike at Ramble Tamble – but it still charges!!”

I was bummed, you see I don’t really know Daniel that well. He bought a PMA from us for his chopper, and I got hang out with him a bit at The Bama Swap and Drags a while back. Cool dude with a cool bike.

The more I thought about it, the more I knew what had to be done. You see, I am not the type of dude who openly accepts help, it’s just damn hard for a guy like me to do. And knowing that the Chopper Gods had smiled down upon Hugh’s HandBuilt – I had to Pay It Forward. So Eddie (he’s new around here, but you’ll be seeing more of him) and I talked it over and made a plan to help get Daniels sweet XS650 chopper back on the road…

So a plan was made.. I ordered materials, parts, and made sure the shop was in good enough shape to go about rebuilding this chopper in a weekend… This past weekend we really killed it. My great friend Dino was there with camera in hand to capture it all…

“And on the first day, the Chopper Gods sent forth a man. A man from Birmingham. A man with a chopper in need. A chopper in need of…… EVERYTHING”

Daniel showed up from Birmingham Alabama with his wrecked choppy.

Took a few minutes to assess the damages…

Scratching my head, yeah it’s that bad…

“Well you see, it used to be like this, but it now its like that”

Oof – that hardtail looks like it’s gone limp…

Bent Frame? Check… Ruined Bars? Check… Smashed fender and sissybar? Check…

This thing by all practical means was completely totalled….

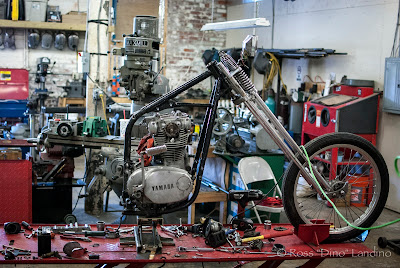

Off the truck and into the shop…

“”Take a good look folks, cuz it’s only getting better from here”

Daniel overlooking the cutdown of whats left of his poor old chopper..

“Wait a minute, this is Daniel’s bike – make him earn it” – haha…

I can see the Craigslist Add Now: “Weld on Hardtail Kit, complete with Fender, Brake Mounts, Sissybar – needs minor work but would be a killer start on your bobber/chopper/cafe/brat/chubber/brubber “

Bars? Yeah, they toast too…

“Bro Wave” on the pile of scrap… I think Daniel has it down…

“Dude, this things gonna need some more cutting” –

Agreed. Check out the lower backbone bracing.

Saving what we could, but even the lower rails were fully tweaked…

Removing the frame slugs from the previous hardtail took some creativity but we finally got em out…

Eddie went to town cutting, blending, grinding and prepping the frame for a rebuild

Daniel Prepping our Mock-Up Motor for the rebuild.

Daniel Says “Safety First” while Eddie says “Son, you aint’ seen nothing yet”

Bryan and Daniel bending up some new Pullback bars. A special focus was given to proper ergonomics on the rebuild.

“Into the fold” – I rarely every build a frame or hardtail for customers or friends.

We got Jiggy Wit It

Daniel – “The Thinker”

Hugh – “The Brains”

Eddie – “The guy with the seriously stanky feet”

Lower Frame rails going back in. Wait what? Yeah thats right, we were putting parts back ON in the first day. Those OEM lower frame rails took some major massaging to get to this point.

Daniel fitting the upper frame rails. We chose to shorten up the tail section from it’s previous incarnation. Zero Drop and 3″ Stretch would look killer, so we went with that.

“It wasn’t me, I’ve been Framed!”

Daniel inspecting the welding process with his Patended “Weld inspection tube”

HHB PMA? Yes sir… And we pulled the points to install a Pamco ignition as well.

The Rear Wheel Bearings were toast, so we inspected the wheel, trued it up and popped new one in… Made for a long day, but we were making some killer progress on a Saturday…

DAY 2

“And on the 2nd Day, the Chopper Gods looked down upon the HHB shop. The Gods were pleased – so they gave the men a 2nd wind to continue the good works.”

Now it should be mentioned, that Daniels chopper was the average amalgamation of all things horrid. When it came to the shop, it had every type of bolt, screw, ziptie and butt connector you could find at the hardware store. Metric, Standard and I’m pretty sure we even found some whitworth bolts on there too…

I expect more from our shop, and in the conquest to make a great chopper for Daniel – only Metric hardware was used in the rebuild. Bungs were installed instead of through holes in the frame, and all this would mean a more reliable and trusty steed. I mean, the bike LOOKS killer, but it’s got a duty to Daniel to be a good one too. Having proper hardware, fabrication, wiring and such will make for a much more enjoyable ride (and a smaller tool bag as well!)

Daniels springer was straight and good to go, but it needed proper bearings and spacers to be machined for a perfect fit. Eddie made that happen on the lathe and things moved along smoothly.

Brian – “The Overthinker”

Measure twice, cut once… (Also know as “Fawk, thats way off”)

Beautifully crafted Pullback Bars – I gotta give Bryan credit for those. He and Daniel made sure they were comfortable and had the proper ergonomics. This bike will be better than ever when it leaves the shop.

Bryan – Making bungholes… He has alot of experience being one – haha.

There must have been 4 different holes in this section of frame from previous tank mounts. We filled and smoothed them out the best we could (This pic was before final smoothing)

A new chain… What new build uses an old cruddy chain? Details like this make for a more enjoyable ride. Spend the extra cash on wear items up front, and less time on the side of the road later..

Daniel “I’m really liking this 2×4 Pine seat, will this be in the HHB catalog soon?”

Eddie “I’m not on Instagram, I promise” – you can follow him under username “Shreddie” – just make sure to ask “How much over stock is them there forks” everytime he posts up a pic of his shovelhead choppy. He loves that…

The look of a man who smokes while fondling a tank full of gas… Serious business folks…

“Damn, this thing is looking like a bike again”

One of Daniels biggest concerns was his rear brake. Being a rear brake only chopper, his old setup was pretty bad. I let him test ride my Slight Hell bike at the Bama Swap and Drags and he knew we could set him up with a killer XS650 rear drum that actually worked.

This is the HHB Rear Brake Pivot Kit, welded and ready to be fitted to the frame.

Simple and effective, just the way we like it.

Fabbed up all new linkage for the rear brake. No cobbled mess of old OEM junk here, all new and working proper.

Fully Adjustable Pivot Stop and a return spring- I’m a big fan of adjustability. Little details like this make it easy to dial in the bike to the rider when it comes time to hit the road.

We used the OEM brake pivot, lever and return spring. Sometimes reinventing the wheel isn’t necessary. But I can say, I’m really proud of this brake setup. We rebuilt the rear drum using all new hardware, springs and EBC Brake Shoes. It’s a killer setup now..

Eddie donated a rear fender he had laying around. It’s the perfect size for the OEM 18″ rear wheel. Some filling of old holes was needed, but it fit just right.

We used the old chain doubled up for proper spacing. This style of bike doesn’t need a tire hugging fender, but one that looks like it came off of a dirt bike probably won’t do either… Just right..

Carbs? Motor? Pegs? Kickstart? Is this thing coming back together or are you just happy to see me… I’m pretty sure Daniel was pitching a tent all weekend…

“A Man and His Machine” – I love this shot…

“After a bit more R&D on the 2×4 seat, I think we are ready to go to market” Now begs the question, will the customers prefer Pine or Oak?

Skinny

What a sissy… Some 5/8″ Cold Rolled stock was pulled from the shelf to create the perfect sissybar for this chop. And like any good weekend build, we ran out of Acetylene so we had to use a Mapp Gas torch to bend it all… I’m betting Daniel spent no less than 4 hours holding that torch this weekend…

PMA Regulator Mount. Nice and tidy.

“And the Chopper Gods sent another gift from the heavens.”

We wanted to hook Daniel up with a Sparx capacitor instead of the battery he was using. He was already running kick only, so why not…

3 Hours later…………… Or was it 4?

Yeah, it’s dark outside… We put in some LONG hours on Sunday building this thing.

“You know, I think this 2×4 seat is really gonna be the next big craze” – Just wait until you see the price of “Period Correct” lumber on Ebay in the next few weeks… Just remember where it all started.

Day 3

“And on the 3rd Day, the Chopper Gods knew that the ascension unto the highways was near”

I’m not gonna kid you, if you think this was the ONLY brew we drank on this build, then feel free to feel sorry for us and send us a care package of your favorite brews (Seriously, we LOVE care packages – haha)

Dino had to take off and get back to school (he’s studying Industrial Design, I’m soo proud of him – haha) , so we got a few less pics on the 3rd day. But the boys and I put in a TON of hours into this thing. It left the HHB shop needing nothing more than a new seatpan and foam, and some minor wiring to be on the road. We cleaned the carbs, installed the Pamco and fired up the engine on the first kick. Eddie put in some major hours and made sure a killer set of pipes got built along with help from Bryan.

You can still see the remnants of the HHB flood in the background.

I honestly cannot be more thankful for the guys I work with. Dino, Bryan, Tevan, and Eddie really make this place feel more like home and less like work all the time. And they all came together to help make this project happen and it happened in a hell of a blur. We basically built an entire chopper in 3 days…

All in all, we were all very pleased with the outcome. This build is probably one of the best things we’ve ever done in the shop. You see, so many people came out and helped us rebuild the shop and get back on our feet after the flood, and we wanted to pay it forward.

All of the guys who helped out donated their time and energy to the build, and HHB donated all of the materials, parts, and even some food and brew to the cause. All Daniel had to do was get here, put in some sweat equity and have a good attitude – And boy did he ever… Pay It Forward whenever you get a chance folks, it really does feel good…

And this is the LAST build to ever come out of this shop, because we just signed the lease on the next big thing….

So you’ll be seeing MORE of HHB goodness soon, and I can’t wait… Thanks so much for all your support. Without a killer network of customers, friends and family – we’d never be able to live this little part of the American Dream.

Thank-You!

Hugh